10

2025

-

04

Buyer Alert: Key Technical Specs for Car paint protection film – Insider Tips from TM Film Factory

Why does a bright surface not mean high quality?

When purchasing invisible car covers, many buyers are attracted by the very bright surface after the paint is installed. But you should know: it is never the surface that determines the quality of car covers, but the core structure and production process.

Bright does not mean scratch resistance; bright does not mean no yellowing; and it does not mean high durability and construction performance.

Five core technical indicators that must be mastered before purchasing

1. Substrate source and purity: We only select high-grade imported TPU particles

TM film factory uses high-purity particles provided by global high-quality TPU raw material suppliers (such as Covestro in Germany and Lubrizol in the United States), and uses its own factory TPU casting equipment to cast once to ensure that the substrate structure is stable, the tensile performance is strong, and it is not easy to yellow.

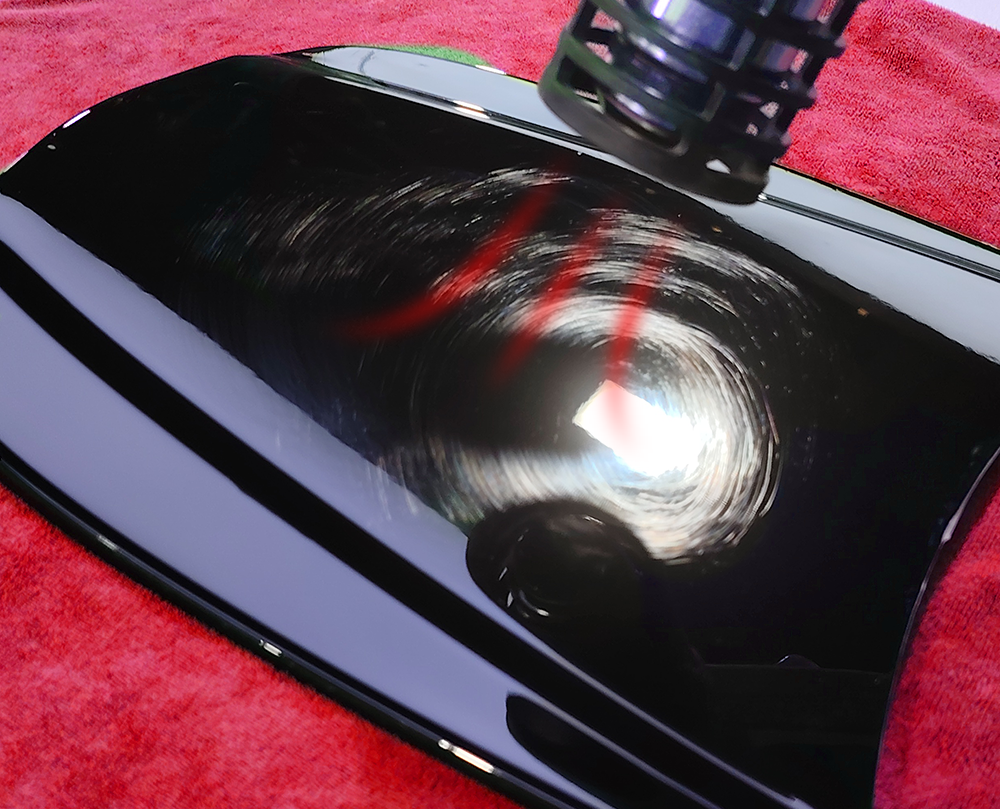

2. Coating process: Nano coating self-repairing

Our independently developed nano-level coating has the ability to repair by heat. Minor scratches will disappear when heated, and it is not afraid of car washing and daily minor friction. At the same time, it has good weather resistance, stain resistance, and UV resistance.

3. Stretch and rebound: high stretch without deformation

Our factory introduces professional multi-functional tensile testing machines in production to conduct standardized tests on each batch of products, with three characteristics of strong stretch + fast rebound + not easy to deform. Ensure that the edge is docile and not warped.

4. Anti-yellowing level: stable and durable

Light, oxidation, and pollutants will make the car cover yellow. All our factory batches have undergone UV aging simulation, salt spray test and high temperature aging test to ensure that the product has a stable 3-5 years of anti-yellowing ability in different climate zones, and is suitable for high temperature markets such as the Middle East and Southeast Asia.

5. Adhesive layer technology: environmentally friendly and paint-proof

The adhesive layer is the key to the fit and later film removal. Poor quality glue is easy to leave residual glue and corrode the car paint. TM film factory has developed its own environmentally friendly polymer glue layer, which is stable in construction and will not leave glue or damage the paint surface after being torn off. Even if it is removed many years later, the integrity of the original car paint can be guaranteed.

How to quickly identify the technical level of a car cover?

Look at the parameters: Do you provide test reports such as elongation, coating thickness, and anti-yellowing level?

Ask about the process: Is it dry, wet, or double-coated? Does it have a nano self-repairing layer?

Check stability: Is there any actual weather resistance, salt spray, and UV test data?

Test sample: It is recommended to take a sample to test the fit and glue layer performance first.

Faced with a wide range of products on the market, truly experienced buyers will not only look at the surface brightness and promotional words, but will have a deep understanding of the materials, processes, and performance indicators.

Car cover is a technical job. Only by mastering these core indicators can you make the most rational choice between price and quality.

TM film factory, strength visible source manufacturing

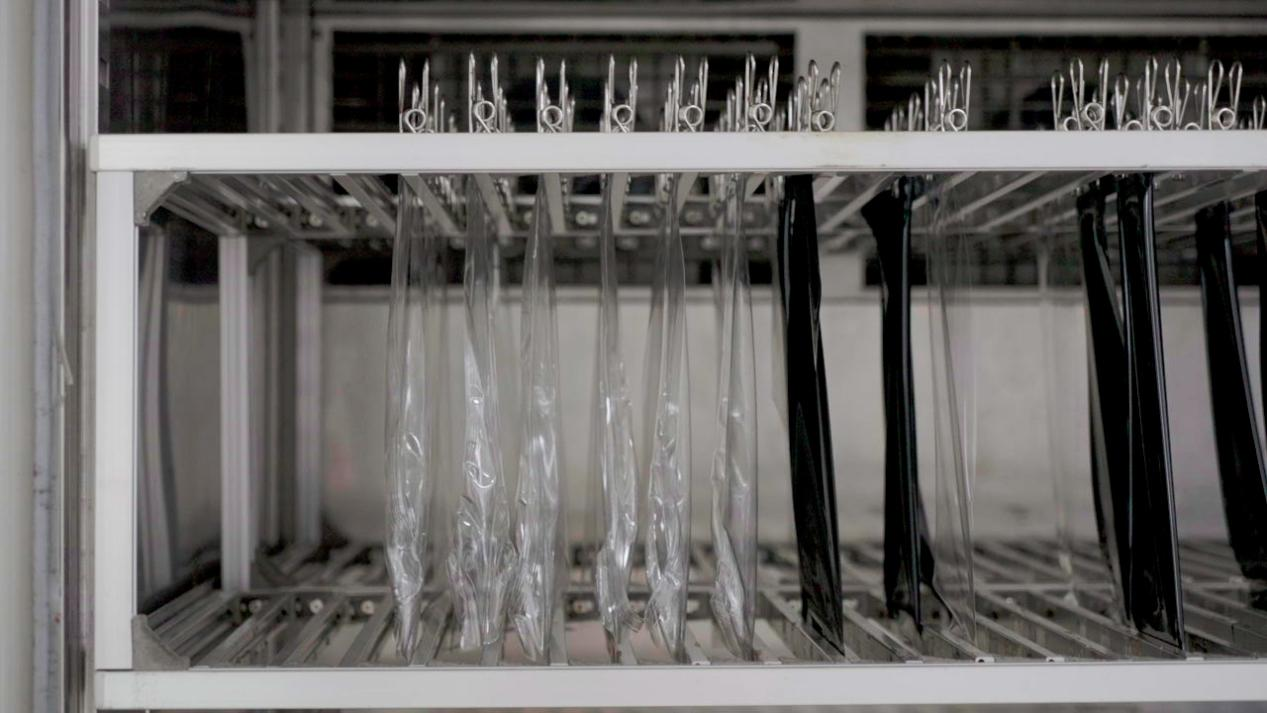

📌 85 acres of integrated modern production base

Own TPU casting equipment + coating equipment + slitting and packaging all in one.

Strict implementation of multiple rounds of quality inspection process, factory inspection program covers:

Tensile strength / Coating thickness / Adhesive strength / Peeling cleanliness / Anti-yellowing / Abrasion test, etc.

We are not a reseller trader, but an original factory with core material technology and processing capability, supporting OEM/ODM customization, stable supply and flexible cooperation.

Translated with DeepL.com (free version)

Relevant News